TETD-75/80

CHEMICAL NAME: Tetraethylthiuram

MOLECULAR FORMULA: C10H20N2S4

MOLECULAR WEIGHT: 296.54

CAS NO: 97-77-8

CHEMICAL STRUCTURE:

SPECIFICATIONS:

| Active Content(%) | 80 | Carrier | EPDM |

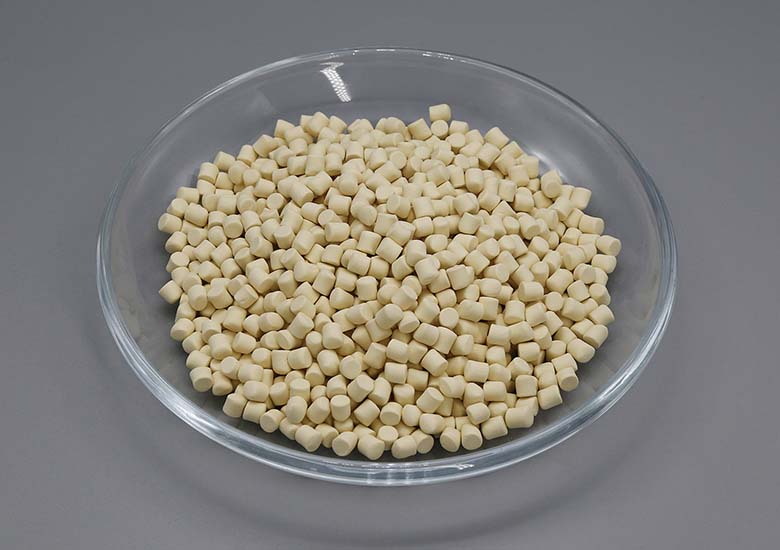

| Appearance | Light-Yellow Granules | Melting Point | 66℃ min |

| Sulfur Content | 32 | Ash Content | 0.3% max |

| Density(g/Cm³) | 1.02 | Heating loss content | 0.5% max |

| Composition | Mixture of 75% Tetraethylthiuram and 25% polymer and dispersing agent | ||

※Binder type can be customized. Except EPDM, others binders, such as SBR, NBR also can be available for.

PROPERTIES:

TETD is an ultra accelerator for NR, SBR, NBR, IIR, BR and latex. It is also a vulcanizer and its effective sulfur content up to 41%.

APPLICATION:

It applies to production of cables, tapes, shoes, tyre tubes and colorful products.

PACKING & STORAGE:

Net weight 25kg/Carton lined PE bag; Net 600 kg/pallet.

Shelf-life: 1 year in its original packaging on conditions of lower temperature(< 35℃) and drying(< 50% RH)

Compared to traditional TETD powders, YLSCH-RBB® TETD-80GE F200 allows::

Dust free products with a complete filtration up to 100µm, no skin sensitization, health guard of operators.

Effective guarantee of activity of TETD due to pre-dispersed masterbatch.

Tack free products at room temperature, convenience and accuracy on ingredients.

Lower Mooney viscosity at lower temperature (50℃), higher quality of dispersion.

Impurity free, blocked filter free of extrusive products, scrap rate reduction and higher productivity thanks to filtration.

Wider compatibility with other elastomers.