RUBBER ACCELERATOR ZBEC-70

CHEMICAL NAME: Zinc dibenzyl dithiocarbamate

MOLECULAR FORMULA: C30H28N2S4Zn

MOLECULAR WEIGHT: 610.21

CAS NO: 14726-36-4

CHEMICAL STRUCTURE:

SPECIFICATIONS:

| Active Content(%) | 70 | Carrier | SBR |

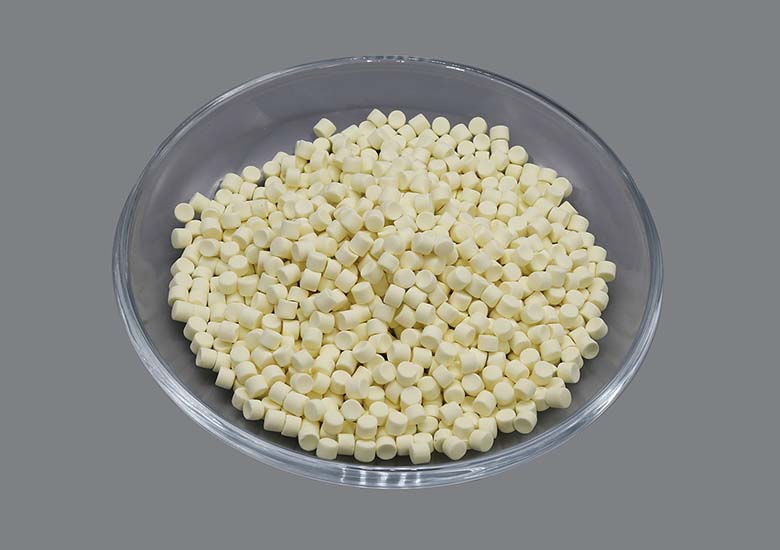

| Appearance | White Granules | Melting Point | 180℃ min |

| Mesh | 100 | Purity | 97.0% min |

| Zinc Content(%) | 10.0-12.0% | Heating loss content | 0.5% max |

| Density(g/Cm³) | 1.2 | 63µm Sieve Residue | 0.5% max |

| Composition | Mixture of 70% Zinc dibenzyl dithiocarbamate and 30% polymer and dispersing agent | ||

PROPERTIES:

ZBEC is an ultrafast dithiocarbamates accelerator which no produce nitrosamine and a primary or secondary accelerator for natural and synthetic rubber such as EPDM, IR, SBR, NBR, IIR, etc. Compared to traditional dithio- carbamates accelerators, ZBEC has higher processing safety. It can activate thiazoles or sulfenamides and can be activated by alkaline accelerators. Vulcanizate accelerated by ZBEC has tensile strength is similar with other dithiocarbamates when dosage is same.

DOSAGE:

For EPDM: 0.8-2.5phr;

For NR, SBR, NBR: 0.8-2.0phr.

PACKING & STORAGE:

Net weight 25kg/PE bags lined carton; Net weight 600 kg/pallet.

Shelf-life: 1 year in its original packaging.Stored in a dry and cool place.

Compared to traditional ZBEC powder, YLSCH ZBEC-70GS allows:

Dust free products with a complete filtration up to 100µm, no skin sensitization, health guard of operators.

Effective guarantee of activity of ZBEC due to pre-dispersed masterbatch.

Tack free products at room temperature, convenience and accuracy on ingredients.

Lower Mooney viscosity at lower temperature (50℃), higher quality of dispersion.

Impurity free, blocked filter free of extrusive products, scrap rate reduction and higher productivity thanks to filtration.

Wider compatibility with other elastomers.

GET THE SPECIFICATION: