Rubber Accelerator NOBS-75/MBS-75

CHEMICAL NAME: N-Oxydiethylene-2-benzothiazole sulfonamide

MOLECULAR FORMULA: C11H12N2S2O

MOLECULAR WEIGHT: 253.35

CAS NO: 102-77-2

CHEMICAL STRUCTURE:

SPECIFICATIONS:

| Active Content(%) | 75 | Carrier | EPDM/EVA |

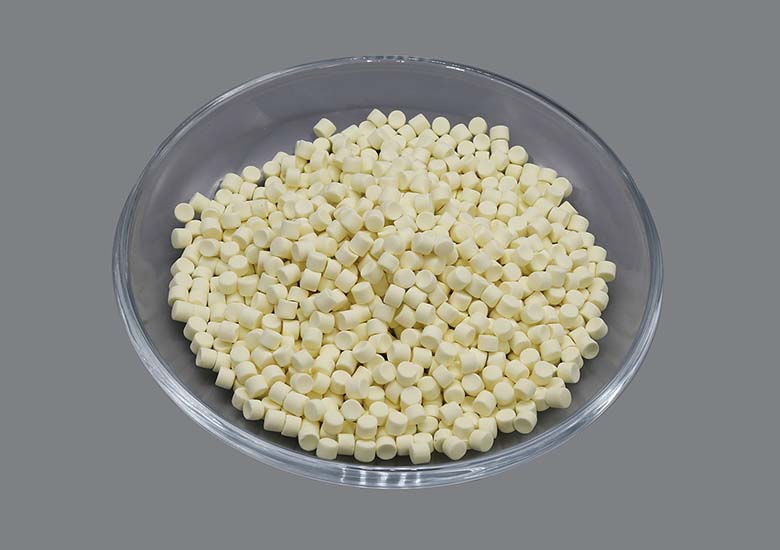

| Appearance | Light-Yellow Granules | Melting Point | 80℃ min |

| Mesh | Ash Content | 0.03% max | |

| Mooney Viscosity ML1+4 50℃ | ≤50 | Heating Loss Content | 0.3% max |

| Density(g/Cm³) | 1.15-1.25 | ||

| Composition | 75% N-Oxydiethylene-2-benzothiazole sulfonamide, 25% EPDM/EVA binder and dispersing agents | ||

Binder type can be customized. Except EPDM/EVA, others binders, such as SBR,NBR also can be available for.

APPLICATION:

NOBS-75,An excellent delayed accelerator. The performance is similar as CZ with better scorch safety Widely used in NR, IR, SBR, NBR and EPDM. Can be used alone or with other vulcanization accelerators such as thiurams, guanidines and dithiocarbamates to improve the activity. Mainly used in manufacture of tires, shoes and belts.

DOSAGE:

Max 0.5phr to avoid blooming.

PACKING & STORAGE:

Net weight 25kg/carton lined PE bag; Net 600 kg/pallet.

Shelf-life: 12 months in its original packaging.

Stored in a dry and cool place.