What is the specific use of HEXA-80 in rubber seals?

2024-07-18

What is foaming agent OBSH-75?

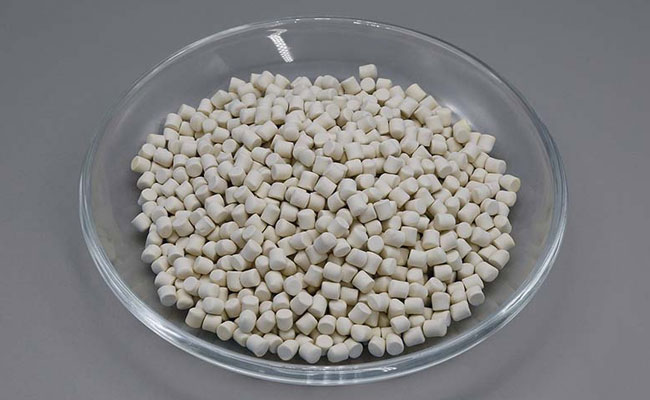

2024-08-02YLSCH-RBB®HEXA-80 (a mixture of 80% hexamethylenetetramine and 20% NBR rubber) is mainly used in tire manufacturing as an accelerator. Accelerators play a key role in the tire manufacturing process and are mainly used to accelerate the vulcanization process and improve tire performance and production efficiency. The following are the specific applications and functions of YLSCH-RBB®HEXA-80 in tires:

- Accelerate the vulcanization process

- Function: YLSCH-RBB®HEXA-80 can significantly shorten tire vulcanization time and improve production efficiency by promoting the vulcanization reaction.

- Advantages: Faster vulcanization speed means higher productivity, helping to reduce production costs.

- Improve tire performance

- Enhanced strength and durability: The vulcanization reaction promoted by HEXA-80 can form a stronger molecular cross-linked structure, improving the strength and durability of the tire.

- Improved wear resistance: By optimizing the vulcanization process, HEXA-80 helps improve the wear resistance of tires, allowing them to maintain good performance over long periods of use.

- Improve the physical and chemical properties of tires

- Heat resistance: Tires treated with HEXA-80 have better heat resistance and can remain stable in high temperature conditions.

- Aging resistance: By enhancing the vulcanization process, HEXA-80 helps improve the aging resistance of tires, making them less prone to cracks and aging in long-term use.

- Chemical Resistance: The application of HEXA-80 can also improve the chemical resistance of tires, making them more resistant to oil, fuel and other chemicals.

- Improve tire elasticity and comfort

- Improve elasticity: HEXA-80 can help form a more uniform vulcanization network, improve the elasticity and softness of tires, and improve driving comfort.

- Shock absorption: After the tire’s elasticity is enhanced, its shock absorption performance is also improved, which can better absorb road vibration and improve driving smoothness.

- Reduce energy consumption and environmental impact of tire manufacturing

- Reduced energy consumption: A more efficient vulcanization process means less energy consumption, helping to reduce production costs and environmental impact.

- Environmental advantages: The application of HEXA-80 accelerator can reduce the emission of harmful substances during the vulcanization process and contribute to environmental protection.

Summarize

The application of YLSCH-RBB®HEXA-80 in tire manufacturing is mainly reflected in the following aspects: accelerating the vulcanization process, improving the strength and durability of tires, improving physical and chemical properties, improving elasticity and comfort, and reducing energy consumption and environmental impact. By using HEXA-80, tire manufacturers can produce high-performance, durable and environmentally friendly tires that meet the market demand for high-quality tires.

YLSCH-RBB® Pre-dispersed Rubber Chemicals Masterbatch range:

Thiazole, Thiuram, Dithiocarbamate, Guandine and Thiourea

1.Accelerators, CBS-80, CTP-80,DPG-80, MBT-80, MBTS-75,TBBS-75, TBzTD-70, TDEC-75, TMTD-80, ZBEC-70 etc

2.Sulfur and Insoluble Sulfur, S-80, IS60-75, IS90-65, DTDM-80, HMDC-70 etc.

3.Antidegradant, MBI-80, MMBI-70, NDBC-70 etc.

4.Scorching Retarders, CTP-80, Retarder E-80 etc.

5.Foaming Agent, ADC-75, OBSH-75, HUD, LDU, DPT etc.

6.Eco-friendly Accelerator, ZDTP-50, TP-50, Retarder E-80, ZBEC-70, TBzTD-70, TiBTD-80,Resorcinol-80 etc.

If you have any demand for Accelerator HEXA-80, please contact us freely.