YLSCH-RBB®CBS-80

2024-03-18

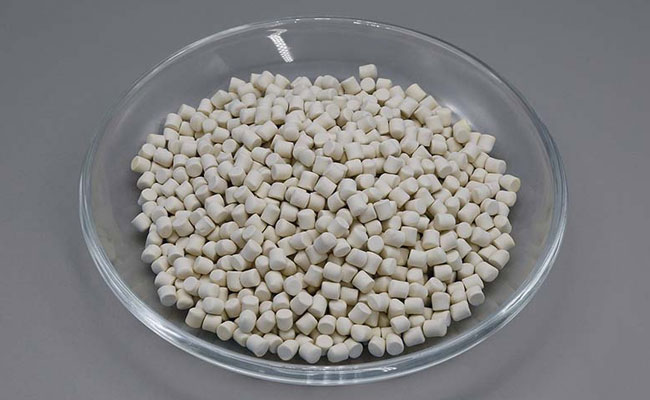

YLSCH-RBB®ACCELERATOR DCBS(DZ)(Granule)

2024-04-03- Development of Rubber Foam Insulation:

The development of rubber foam insulation products has received widespread attention in recent years. With the continuous advancement of science and technology, the manufacturing technology of insulating foam rubber products has been improved and innovated. The development of new materials, such as improved masterbatch, has further improved the performance of rubber foam insulation products. The use of masterbatch as raw materials has gradually become mainstream. The development of this method is important for improving production efficiency and reducing production costs. Cost, enhanced product consistency and quality control all have important implications.

- Commonly used masterbatch particles for rubber foam insulation products:

ZDMC-75, DPTT-70, ZDEC-80, ZDBC-80, MBT-80, S-80, ADC-75

- The development of masterbatch for rubber foam insulation products:

As a raw material for insulating foam rubber products, masterbatch has experienced a development process from introduction to improvement, optimization and automated production. Its wide application has promoted the improvement of production efficiency, enhanced quality stability and expansion of application fields of insulating foam rubber products. Early foreign manufacturers included Rheinland Chemical. Later, the supply of such products on the market was gradually produced by manufacturers from China. Representative manufacturers include QINGDAO YLSCH INDUSTRY&TRADE CO., LTD. The quality of pre-dispersed masterbatch particles produced in China has been widely recognized at home and abroad. Recognized by customers, it has become one of the representatives of pre-dispersed masterbatch particles on the market. With the improvement of global environmental awareness, the market prospects of new environmentally friendly masterbatch products are promising. Representative products include ZDMC-75, DPTT-70, ZDEC-80, ZDBC-80, MBT-80, S-80, ADC-75 Especially in foreign markets, ZDMC-75 is widely used and in large quantities.

- ZDMC-75

Composition:75% zinc dimethyl dithiocarbamate, 25% elastomer binder and dispersing agent;

YLSCH-RBB®ZDMC-75 is an accelerator for the rapid vulcanization of natural- and synthetic rubber such as NBR, SBR and EPDM;

It offers longer scorch time and a faster total curing time than YLSCH-RBB® ZDBC-80, ZDEC-80 and ZEPC-80. The addition of thiuram and thiazole accelerators retards the start of the vulcanization and increases processing safety. It is also used in small amounts for secondary acceleration and for the activation of mixes. It contains ethylene propylene diene rubber as a binder. It is applicable in bright-colored articles, transparent articles and cables.

- DPTT-70

Composition: 70% Bis(piperidinothiocarbonyl)hexasulphide,30% elastomer binder and dispersing agent;

- YLSCH-RBB®DPTT-70is an ultra-accelerator for the vulcanization of natural-

and synthetic rubbers;

It also functions as sulfur donor for vulcanization with low or no free sulfur. It causes very rapid and scorch-safe vulcanization of rubber along with good processing safety. It acts as activating secondary accelerator, when combine with other mercapto- or sulphenamide-type-accelerators. It is also used in conjunction with other thiuram accelerators. It offers heat resistant vulcanizates with good aging properties. It is suitable for all heat resistant technical articles, e.g. hoses, seals and gaskets based on EPDM and IIR.

- ZDEC-80

Composition:80% Zinc dibenzyldithiocarbamate,20% elastomer binder and dispersing agent;

YLSCH-RBB®ZDEC-80 causes very rapid vulcanization of natural and synthetic rubbers such as SBR, NBR and EPDM.;

It provides very good tensile and resilience properties, longer scorch time and a faster curing rate. It receives an additional activation from basic accelerators. It is recommended to add antioxidants for improving the resistance to aging especially of NR and IR. YLSCH-RBB®ZDEC-80 is also used in small amounts for secondary acceleration and activation of mixes which are going to be cured with mercapto or thiuram accelerators.

- ZDBC-80

Composition:80% zinc dibutyl dithiocarbamate, 20% elastomer binder and dispersing agent;

YLSCH-RBB®ZDBC-80 is an accelerator for the rapid vulcanization of natural- and synthetic rubbers such as SBR, NBR and EPDM.

It is also used in small amounts for secondary acceleration and activation of mixes cured with mercapto or thiuram accelerators. It offers the vulcanizates very good tensile and resilience properties. It is recommended to add antioxidants to improve resistance to aging especially of NR and IR. The addition of thiuram and thiazole accelerators can retard the curing rate and enhances processing safety. It has a shorter scorch time and a slower total curing time than YLSCH-RBB® ZDEC-80, ZEPC-80 and ZDMC-80. It contains ethylene propylene diene rubber as a binder. It is designed for technical articles of all kinds, e.g. footwear and cables.

- MBT-80

Composition:80% mercaptobenzothiazole, 20% elastomer binder and dispersing agent;

YLSCH-RBB®MBT-80 is a semi-ultra, multi-purpose accelerator with a long plateau effect. It is suitable for NR, SBR, IIR and CR;

It offers vulcanizates with good physical properties. In sulfur-free compounds, it acts as an anti-scorch agent and in CR compounds as a retarder. It is activated by basic accelerators such as aldehyde-amine, guanidine, thiurams and dithiocarbamates. It contains ethylene propylene diene rubber (EPDM) as a binder. It is designed for technical rubber articles of all kinds, e.g. treads, carcasses, air hoses, conveyor belts, driving belts, hoses and cable insulation.

- S-80

Composition:80% sulfur, 20% elastomer binder and dispersing agent;

YLSCH-RBB®S-80 is a curing agent for all natural- and synthetic rubbers;

It improves resistance against aging and dynamic fatigue. In soft compounds, good dispersion of sulfur is of particular advantage. It contains ethylene propylene diene rubber (EPDM) as a binder. It is applicable in bright-colored compounds that have to be free of sulfur stains, rubber articles which have to withstand dynamic stress.

- ADC-75

Composition: 75% Azodicarbonamide, 25% elastomer binder and dispersing agent

YLSCH-RBB®ADC-75 Can be used for foaming of various rubbers such as CR, EPDM, IIR, NBR (NBR/PVC) and SBR. Especially used for foaming with tiny and uniform pores.

YLSCH-RBB®ADC-75 has a relatively high foaming temperature (200 °C-210 °C). Adding a small amount of foaming activator can effectively reduce the foaming temperature of ADC-75. This product will not increase the odor of foaming products. Suitable for all foam or foam rubber products.

- Binder type can be customized. Except EPDM/EVM, other binders, such as CR, SBR, ARalsocanbeavailablefor.

- Customizable product colors.

There are many types of masterbatches that can be used in rubber products. If you are interested, please feel free to contact us.