YLSCH-RBB®Rubber Retarder E (Vulkalent E/C )

2024-03-05

YLSCH-RBB®CBS-80

2024-03-18YLSCH-RBB®CaO-80 is a mixture of 80% calcium oxide and 20% polymer and dispersant.

Product Name: YLSCH-RBB®CaO-80

Chemical Name: Calcium oxide

Synonyms:Calciumoxide. CaO. YLSCH-RBB CaO

Molecular Formula: CaO

Molecular Weight:56.08

Cas No.:1305-78-8

Quality Standard:

| Active Content(%) | 80 | Melting Point | 2570℃ |

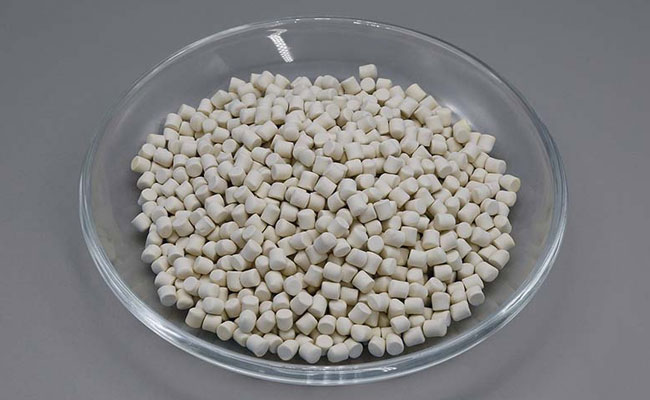

| Appearance | Grey-white Granules | Boiling point | 2850℃ |

| Carrier | SBR | Purity | 98%min |

| Filtration (microns) | 200 | Loss on ignition (950℃,2h) | 3.0% max |

| Density(g/Cm³) | 2.10 | Mean grain size | 12μm max |

| Ash Content(%) | 81.0 | 38μm sieve residue | 0.1% max |

| Composition | Mixture of 80% Calcium oxide and 20% polymer and dispersing agent | ||

※Binder type can be customized. Except SBR, others binders, such as EPDM,NBR also can be available for.

APPLICATION:

Extruded products (seals, tubes), conveyor belting, rollers, cable sheaths, rubber flooring, etc.

EFFECT:

Moisture adjustment: Hygroscopic masterbatch CaO is mainly used to adjust moisture during the rubber mixing process. Moisture control is critical to rubber processing and vulcanization processes. By hygroscopic masterbatch, the moisture content in rubber compounding can be more accurately managed, helping to maintain the consistency and performance of rubber products.

Additives in rubber mixing: In addition to moisture adjustment, hygroscopic masterbatch particles may also contain other additives to improve the rubber’s processing performance, vulcanization speed and other characteristics.

Package:Vacuum-aluminum foil bag package,1kg/bag, 25bags/carton, Net Weight 750kgs per pallet.

Storage Validity: 6 months in its original packaging.

Storage method:

In order to ensure the performance and quality of hygroscopic masterbatch particles, the following points need to be noted during storage:

Moisture-proof storage: Since the hygroscopic masterbatch particles are hygroscopic, it is recommended to store them in a dry and moisture-proof environment to prevent moisture absorption from affecting their performance.

Avoid moisture: Hygroscopic masterbatch pellets should be stored in sealed containers to avoid moisture intrusion. This helps maintain its hygroscopic properties and stability.

Avoid direct sunlight: Avoid direct exposure of hygroscopic masterbatch particles to sunlight to prevent high temperature and ultraviolet rays from adversely affecting them.

Keep away from harmful substances: When storing, keep away from acids, alkalis, organic matter and other substances that may have adverse effects on hygroscopic masterbatch particles.

Regular inspection: Regularly check the storage conditions to ensure that the packaging of hygroscopic masterbatch particles is intact and that moisture-proof measures are effective.

If needed, we can supply small qty sample for lab trial any time. please feel free to contact us.