YLSCH-RBB®TMTD-80

2024-01-19

YLSCH-RBB®Rubber Retarder E (Vulkalent E/C )

2024-03-05YLSCH-RBB®NOBS-80 is composed of 80% dibenzothiazole disulfide and 20% EPDM/EVA adhesive and dispersant

Use Characteristics: The curing accelerator YLSCH-RBB® NOBS-80 causes a considerably long scorch time, great processing safety and a fast full cure. YLSCH-RBB® NOBS -80 is used as primary accelerator for the low sulphur vulcanization or in combination with dithiocarbamate and thiuram accelerators. The vulcanizates obtained provide good ageing resistance and compression set. The scorch times of mixes containing YLSCH-RBB®NOBS -80 in combination with thiuram and dithiocarbamate accelerators are noticeably reduced. Combinations of YLSCH-RBB®NOBS -80 and YLSCH-RBB® TMTM-80 have proved particulary favourable. They cause very short total curing times – though the mixes have good scorch resistance and a very high degree of crosslinking, even in relatively small amounts. Thiourea derivatives have strong secondary acceleration effects on YLSCH-RBB®NOBS -80, especially in mixes containing small amounts of sulphur. In mixes that are accelerated with mercaptanes and thiurams, YLSCH-RBB®NOBS -80 may reduce the onset of cure.

| Active Content(%) | 80 |

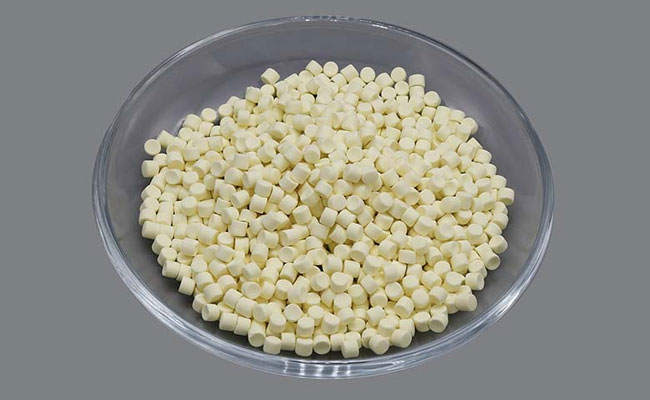

| Appearance | Light-yellow Granules |

| Mooney Viscosity ML1+4 50℃ | ≤70 |

| Density(g/Cm³) | 1.10 |

The main advantages of NOBS-80 masterbatch include:

1. Easy to carry and store: NOBS-80 exists in the form of masterbatch particles, which is easier to carry and store than liquid or bulk powder. This helps facilitate shipping and reduces handling complexity.

2. Accurately control the addition amount: The form of masterbatch particles makes it easier to accurately control the addition amount of NOBS during production, ensuring that the amount of vulcanization accelerator used meets product requirements.

3. Improve production efficiency: Since NOBS-80 masterbatch particles can be directly added to rubber mixing, the vulcanization accelerator can be processed more quickly and conveniently during the production process, thus improving production efficiency.

4. Reduce flying dust: The form of masterbatch particles reduces the flying dust generated by the vulcanization accelerator during the rubber mixing process, improves the cleanliness of the working environment, and helps maintain the health and safety of workers.

5. Uniform dispersion: NOBS-80 masterbatch particles are usually easier to achieve even dispersion with rubber during production, helping to ensure uniform distribution of NOBS and improving vulcanization consistency.

NOBS-80 masterbatch is mainly used as vulcanization accelerator and additive for rubber products. Its main uses include:

- Rubber vulcanization accelerator: NOBS-80 is mainly used to promote the vulcanization reaction of rubber. Vulcanization is a key step in rubber processing. Through the action of sulfur and vulcanization accelerators, the polymer chains in the rubber can be cross-linked, thereby changing the properties of the rubber and making it more elastic, wear-resistant and aging-resistant.

- Improve the performance of rubber products: NOBS-80 can improve the elasticity, wear resistance and aging resistance of rubber, giving rubber products better performance. This is particularly important when manufacturing rubber products such as tires, rubber tubes, and rubber mats.

- Accelerate vulcanization reaction: NOBS-80 helps accelerate the reaction speed of rubber vulcanization, thereby improving production efficiency. Accelerating the vulcanization reaction is particularly important in certain application scenarios where large quantities of rubber products need to be produced quickly.

- Used in the production of rubber products: NOBS-80 masterbatch pellets are usually added directly to rubber mixing to facilitate use in the production of rubber products. It is widely used in the rubber industry, including the manufacture of tires, rubber tubes, rubber mats and other rubber products.

YLSCH-RBB® Pre-dispersed Rubber Chemicals Masterbatch range:

Thiazole, Thiuram, Dithiocarbamate, Guandine and Thiourea

Accelerators, CBS-80, CTP-80,DPG-80, MBT-80, MBTS-75,TBBS-75,

TBzTD-70, TDEC-75, TMTD-80, ZBEC-70 etc

2. Sulfur and Insoluble Sulfur, S-80, IS60-75, IS90-65, DTDM-80, HMDC-70 etc.

3. Antidegradant, MBI-80, MMBI-70, NDBC-70 etc.

4. Scorching Retarders, CTP-80, Retarder E-80 etc.

5. Foaming Agent, ADC-75, OBSH-75, HUD, LDU, DPT etc.

6. Eco-friendly Accelerator, ZDTP-50, TP-50, Retarder E-80, ZBEC-70, TBzTD-70, TiBTD-80 etc.

YLSCH-RBB® rubber chemicals can be applied for:

- Automotive rubber seal strip

- Technical rubber parts, wiper blades, seal, hose, belt, anti-vibratory etc.

- Rubber tires

- Rubber shoes sole, boots etc

- Insulating foam products

- Wiring & Cables

If needed, we can supply small qty sample for lab trial any time. please feel free to contact us.