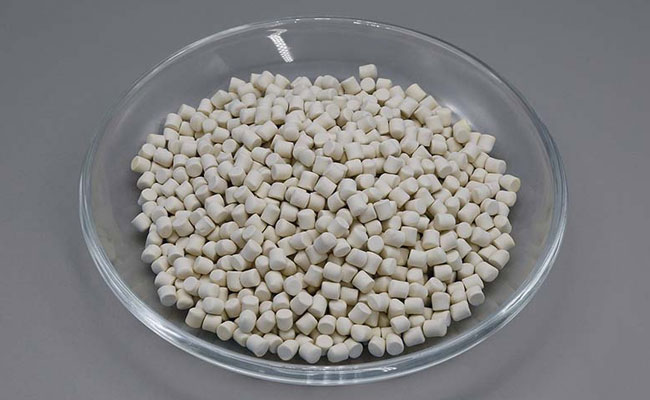

YLSCH-RBB® Pre-dispersed Rubber Accelerator Masterbatch DPG-80

2023-03-27

YLSCH-RBB® Resorcinol-80/R-80

2023-04-24YLSCH-RBB®Rubber Additives Predispersed Masterbatches

Rubber pre-dispersed masterbatch

Traditional powder additives

- Environmental protection

The use of pre-dispersed rubber masterbatches of rubber additives to replace ordinary powder rubber processing aids can reduce and eliminate chemical fumes and dust flying.

- Energy saving

At the same time, it can improve dispersion effect and processing performance, improve product quality, facilitate use, reduce mixing temperature, facilitate storage and automatic measurement.

- Excellent dispersibility

Improve dispersion and shorten dispersion time. And can meet the requirements of modern rubber low temperature continuous mixing.

The principle of powder granulation:

(1) Adsorption between solid particles (2) Mutual diffusion on the surface of solid particles

(3) Adhesive or softener bonding (4) Mechanical bonding force on the surface of solid particles

YLSCH-RBB® Specific application of rubber additives pre-dispersed masterbatch

Our products are used in tires, conveyor belts, automotive products, oil seals, shoe soles, wires and cables, industrial products and other fields. Professional service for rubber product manufacturers, solving problems such as difficult processing and dispersion of rubber additives, unstable product performance, etc.

YLSCH-RBB® Practical Application Advantages of Masterbatch – Eliminate Hidden Costs

Loss in use of powder

- Under dust collection conditions and corridor sweepings will cause up to 5% loss

- More finished and semi-finished products are scrapped

- Cost of waste disposal

- Substituting lost substances must be purchased

- Operating costs – health, safety, PPE, insurance, etc.

Loss in the use of masterbatch:

- There is almost no loss of raw materials in the dust collector and the ground

- Reduction in the scrapping of finished and semi-finished products

- No waste disposal cost

- There is no loss material that must be purchased

- Operational costs—health, safety, PPE personal protective equipment, insurance and other issues are reduced.

Application advantages of masterbatch – eliminate hidden material costs and increase profit margins

1. Potential operational loss

- waste

- housekeeping

- obsolete

Lost in dust collectors, grinding and other waste processes; waste disposal.

2. Potential operational loss – inconsistent vulcanization rate

- mix

- Preparation and ingredients

- Final touches

inconsistent vulcanization rate

non-dispersible particles

Scrapping of semi-finished and finished products

The waste must be replaced with another batch of material

can lead to long-term quality problems

3. When problems occur

- The further down the process, the more money is spent on the issue

unforeseen downstream costs

YLSCH-RBB®Total Cost Calculations Using Powders vs. Masterbatches

| Performance | Production cost using powder | Production cost using masterbatch |

| initial cost | A = $2.00 per kg, buy 100 kg total | B = $4.00 per kg. Buy 100 kg |

| Total $200 | Total $400 | |

| (Powder raw material cost) | (pre-dispersed masterbatch cost) | |

| Mixing Loss | Up to 5kg (mixing loss up to 5%) | loss Little or no |

| Complementary Mixing Loss | That is the lost 5kg, $100.00 | little or no |

| Finished and semi-finished products | Although the powder may only occupy a small portion, | none |

| scrap supplement | But there is a 1% loss that may correspond to the overall | |

| Material loss ($200 and above) | ||

| Other supplementary loss materials | Abandoned is equivalent to total loss | none |

| (rubber, etc.) | (potentially $200 or more) | |

| cleanup costs | $20 or more | little or no |

| Worst Case Total | 3.1 times more than the initial cost | 2.0 times the original cost |

Which one is the more efficient product?

- Lower initial cost using powder

- Reduce scrap and waste with masterbatches

- Potential savings of 55% using masterbatch

《Rubber processing rubber mixing workshop dust prevention regulations GB 21657-2008》

According to the national standard, if powder compounding agent is used, not only will the rubber mixing workshop be filled with dust, but raw materials will be wasted, and the cost for dust prevention will also be a considerable expense. Although the national standard does not directly stipulate that the use of masterbatch instead of powder is prohibited, it can be seen that the problem of dust prevention cannot be underestimated.

As a supplier, YLSCH-RBB technicians will use our professional knowledge to provide technical assistance for issues related to product use,

For more information on predispersed masterbatches, please visit

https://www.ylsch-rbb.com/products/pre-dispersed-masterbatch/

A list of our masterbatch products is available for download.

If you have any questions about predispersed masterbatches, please feel free to keep in touch with us.