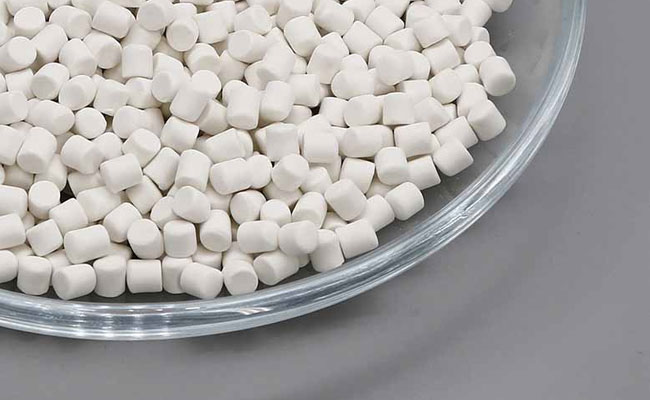

Common pre-dispersed rubber additives (masterbatch)

2022-09-15

【Introduction of flame retardants】YLSCH-RBB® Antimony Trioxide

2022-11-031. The definition of foaming agent

The so-called foaming agent is the substance that makes the target material pore, and it can be divided into three categories: chemical foaming agent, physical foaming agent and surfactant. Chemical foaming agents are those compounds that can release gases such as carbon dioxide and nitrogen after being decomposed by heating and form pores in the polymer composition; physical foaming agents are foam pores that change through the physical form of a certain substance. , that is, formed by the expansion of compressed gas, the volatilization of liquid or the dissolution of solid; the foaming agent has high surface activity, which can effectively reduce the surface tension of the liquid, and arrange the double electron layer on the surface of the liquid film to surround the air, forming bubbles, which in turn form foam from individual bubbles. Therefore, its main function is to fill the gap, and it has some fixed functions. Generally speaking, foaming agents are divided into rubber foaming agents, glass foaming agents, cement foaming agents, concrete foaming agents, plastic foaming agents, and polyurethane foaming agents. conditions to choose. Focus on the analysis of AC foaming agent and OBSH foaming agent.

2. Classification and function of foaming agents

AC foaming agent Chemical name: azodicarbonamide Molecular formula: C2H4O2N4 is the foaming agent with the largest amount of initiation, the most superior performance and the most extensive use. It is used in synthetic materials such as polyvinyl chloride, polyethylene, polystyrene, polyamide, ABS and various rubbers. Widely used in slippers, soles, insoles, plastic wallpaper, ceilings, floor leather, artificial leather, thermal insulation, sound insulation materials and other foaming. Foaming agent AC has the characteristics of stable performance, non-flammable, non-polluting, non-toxic and tasteless, non-corrosive to molds, non-dyeing of products, adjustable decomposition temperature, and does not affect curing and molding speed. This product can be foamed under normal pressure or under pressure, and it can be evenly foamed, and the pore structure is ideal.

- Under normal circumstances, this product should be added with an appropriate amount of activator (such as zinc oxide, stearate, carbonate and phosphate) according to the performance of the product to adjust the decomposition temperature. The amount of the activator should depend on the type of activator and the quality of AC. And product performance is determined by tests.

- The dosage of AC foaming agent also depends on the performance of the product. Generally from 0.1-30 servings. For example, about 5 parts of photopolymer, about 15-25 parts of pressed foam sponge and soft and hard sponge, and about 0.1 part of polyethylene metal wire.

- Storage and transportation: Store in a ventilated, cool and dry place.

- Packing: 25kg/bag. Processing sponge rubber products, generally from 1-20 copies. Depending on product performance. The vulcanization conditions of the model products, the formula selected by the small coordination experiment, must be carried out in the pilot test and the batch test. The final modified formula makes the rubber fully vulcanized. Generally, it can be used after a period of time after setting.

OBSH foaming agent chemical name: 4,4-oxodibenzyl hydrazide, molecular formula: C12H14O5H4S2, decomposition temperature: 150~165℃, gas output (20℃, 760mmHg) ml/g: 120~130, decomposition temperature (℃) 140~160 particle size (mesh) 300, OBSH is a special foaming agent for rubber, which has the characteristics of uniform nucleation and fine and uniform foaming pore size. OBSH foaming agent has stable gas composition and can obtain products with good cell structure. It is the preferred foaming agent for high-quality rubber products. OBSH foaming agent has no induction period for decomposition, fast decomposition speed, smooth degassing without sudden burst, etc. It makes the foaming process easy to control.

- When a single product is used, it can produce a fine, high-quality and uniform pore structure, and the foamed product is odorless, tasteless, pollution-free and non-discoloring, especially suitable for odorless and light-colored foamed products.

- It can be applied to natural rubber and various synthetic rubbers (such as: EPDM, SBR, CR, FKM, IIR, NBR) and thermoplastic products (such as PVC, PE, PS, ABS), and can also be used for rubber-resin mixtures used in.

- It has good insulation and can be used in the manufacture of wires and cables.

- Under certain circumstances, it can act as both a foaming agent and a cross-linking agent in the curing mechanism.