Introduction of Accelerator for Medical Latex Products

2022-03-18

Pre-dispersed Masterbatch

2022-09-15◆Product origin and development

1. Product origin: ZBEC (ZBDC) is a dithiocarbamate accelerator developed by an American company. This product is not easy to produce nitrosamines and can be used to replace accelerators ZDEC (EZ/ZDC), ZDBC (BZ), ZDMC (PZ) and so on.

2. Product development: ZBEC (ZBDC) products have been continuously optimized by several production plants in China after 2008, and can completely replace foreign products. Now the quality has been recognized by domestic and foreign customers, and it has become one of the mainstream environmental protection products in the market. One, especially the ZBEC products produced by Hebi Yuanhao New Materials Co., Ltd. With people’s attention to health and environmental protection, the market prospects of environmentally friendly new rubber additives are promising.

◆Basic product information

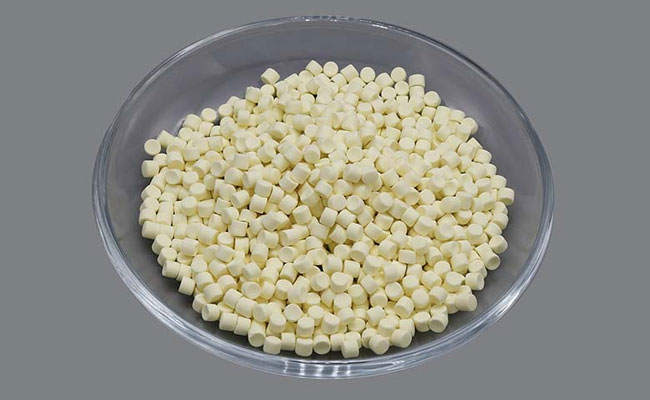

1. Product name: ZBEC (ZBDC, ZTC)

2. Chemical name: Zinc dibenzyl dithiocarbamate

3. CAS NO:14726-36-4

4. EINECS: 238-778-0

5. Molecular weight: 610.17

6. Properties: Soluble in ethanol and benzene, insoluble in water.

◆Product application

1. Ultra-speed accelerator: This product is a main or auxiliary accelerator with fast vulcanization, which belongs to ultra-speed accelerator. It is suitable for natural rubber and synthetic rubber. It is also a fast accelerator in NR and SBR latex. This product is a safe secondary amino dithiocarbamate accelerator.

2. Anti-scorch performance: Among all the dithiocarbamate accelerators, ZBEC has long anti-scorch performance, good operation safety, and good anti-early vulcanization effect in latex.

3. Application of environmental protection: its vulcanization activity temperature is low, and the operation is relatively safe. As an environmentally friendly product, it can be used in products instead of ZDEC, ZDBC, and ZDMC products. It is an excellent active agent for thiazole and sulfenamide accelerators. Compared with these three products, ZBEC cure time is long, while ZDEC cure time is fast.

4. When the dosage is the same, the tensile stress of ZBEC and other dithiocarbamate products are similar.

5. It can be used as main or auxiliary accelerator in synthetic rubber such as NR, EPDM, IR, SBR, NBR, IIR.

◆DOSAGE:

1. Dosage: The general dosage is 0.5-1.5 copies. EPDM: 0.8-2.5 parts, NR, SBR, NBR: 0.8-2 parts.

Note: The specific addition and addition amount can be selected after testing according to the product and formula.

![Environmentally friendly accelerator ZBEC [substitute for EZ, BZ, PZ]](/wp-content/uploads/2019/12/ylsch-website-logo-1.png)